Profitable Klimawende dank enaDyne

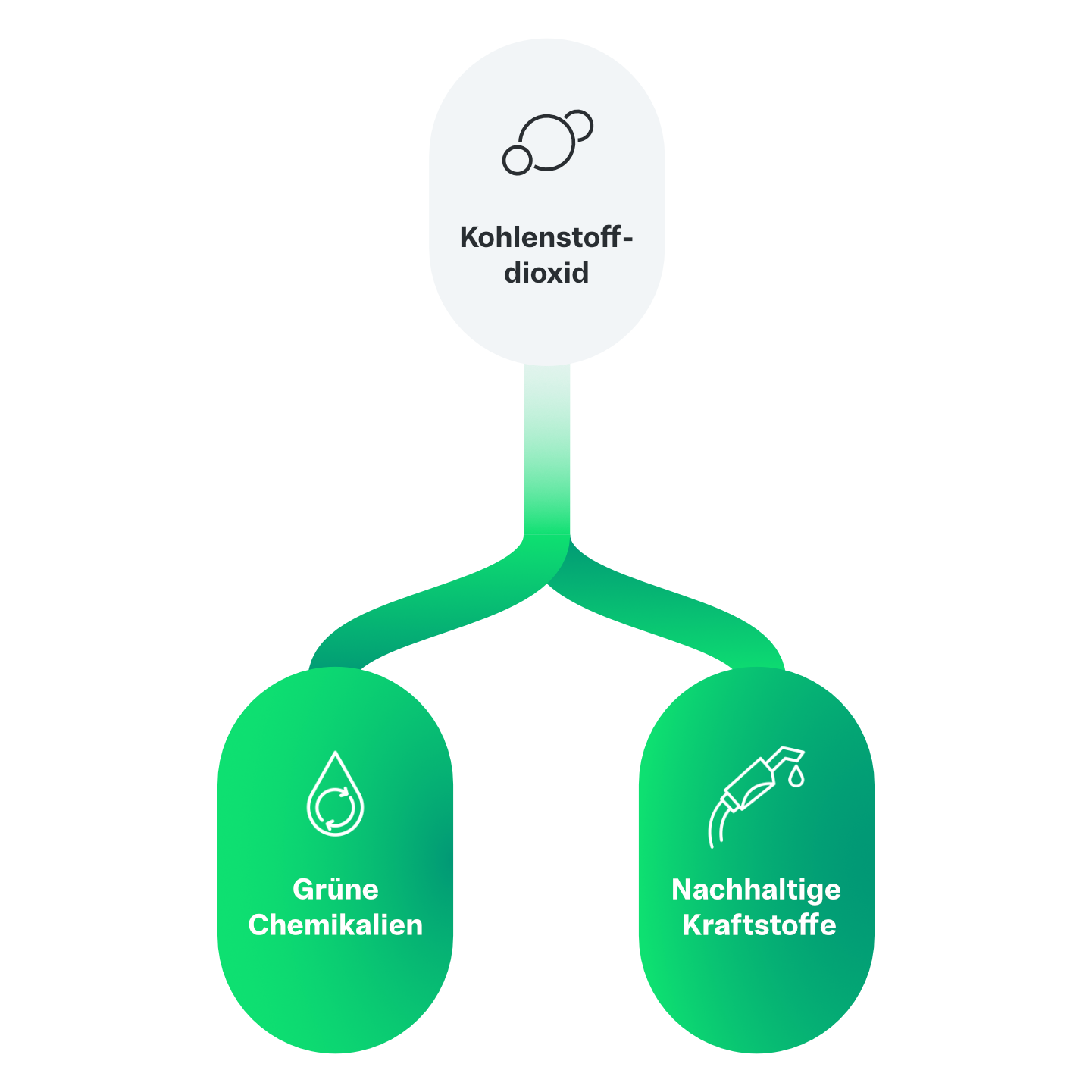

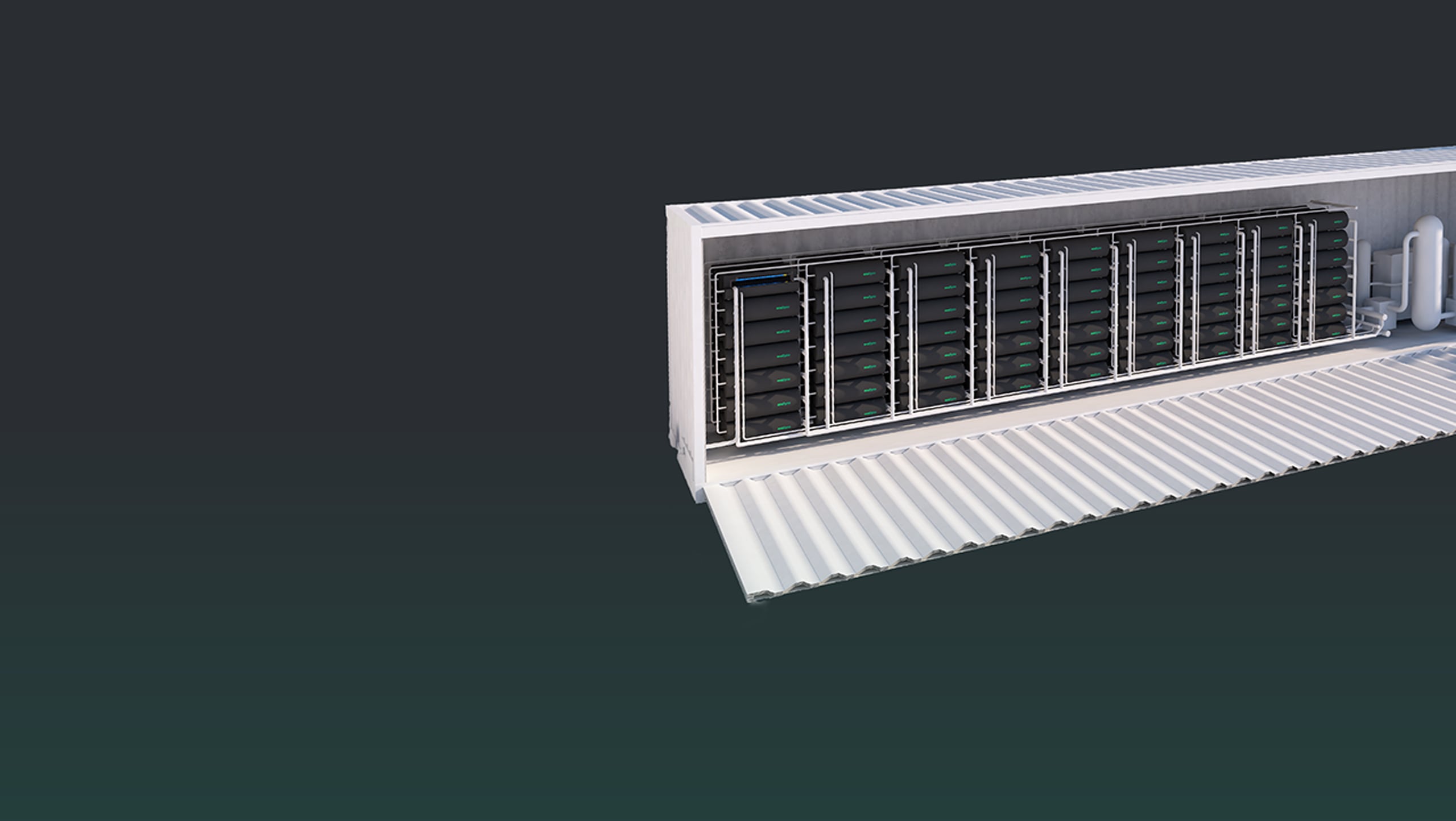

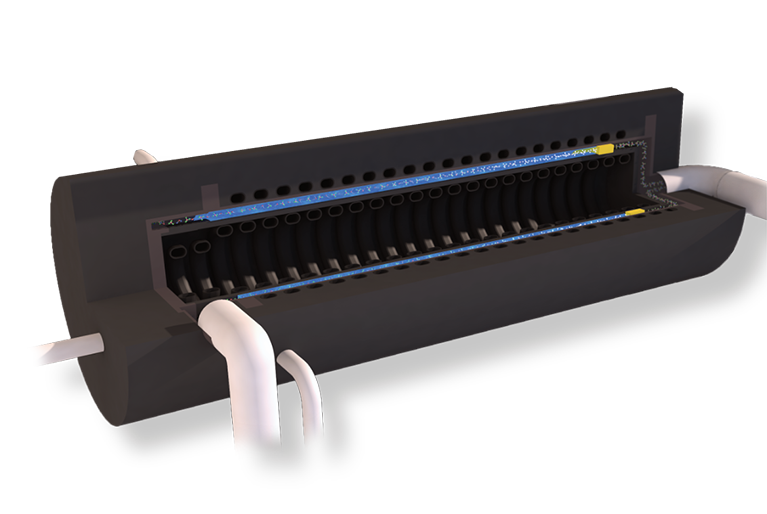

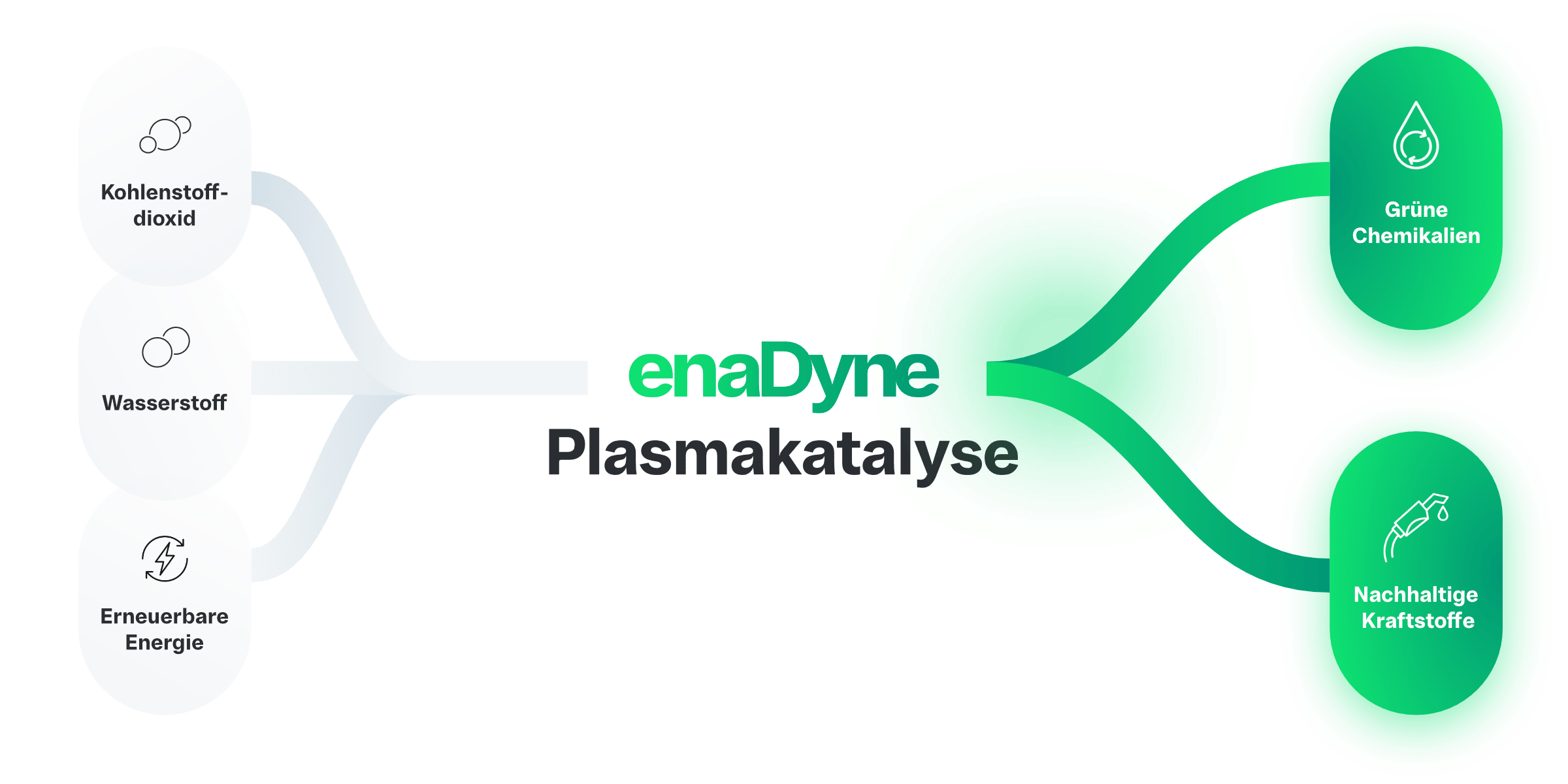

Mit unserer einzigartigen plasmabasierten CO2-Recycling-Technologie helfen wir nicht nur dabei, schädliche Emissionen drastisch zu reduzieren. Wir produzieren dabei auch nachhaltige Rohstoffe – und das mit Profit. So wird die Klimawende von einer vermeintlich teuren Verpflichtung zu einer wirtschaftlich attraktiven Chance. enaDyne unterstützt Unternehmen dabei, die Klimawende deutlich wettbewerbsfähiger zu gestalten.

Erfahren Sie mehr darüber wie wir Klimaschutz und Rendite verbinden.

Philipp Hahn

Co-Founder und CEO

Wir beantworten gerne Ihre Fragen zu unserer Technologie oder einer Zusammenarbeit.

Verändern Sie mit uns die Welt!

Sie haben Interesse an unserer Technologie oder Ihrer Anwendung? Wir beantworten Ihnen gerne alle Fragen.